During construction in winter, a dry and ventilated place should also be selected, and the unused building formwork should be classified and stored in a timely manner, and the formwork should not be directly exposed to the outside, so as to avoid the deformation of the formwork due to erosion or low temperature effects such as frost, rain and snow, etc., deterioration, fading and other problems, affecting subsequent use.

1. If the construction is in winter, the ice, snow and soil on the formwork should be removed before the formwork is supported, and the sundries, ice and snow in the formwork must be cleaned up after the formwork is supported, and no watering is allowed. In case of strong winds (level 5 and above), the assembly and hoisting of large formwork shall not be carried out.

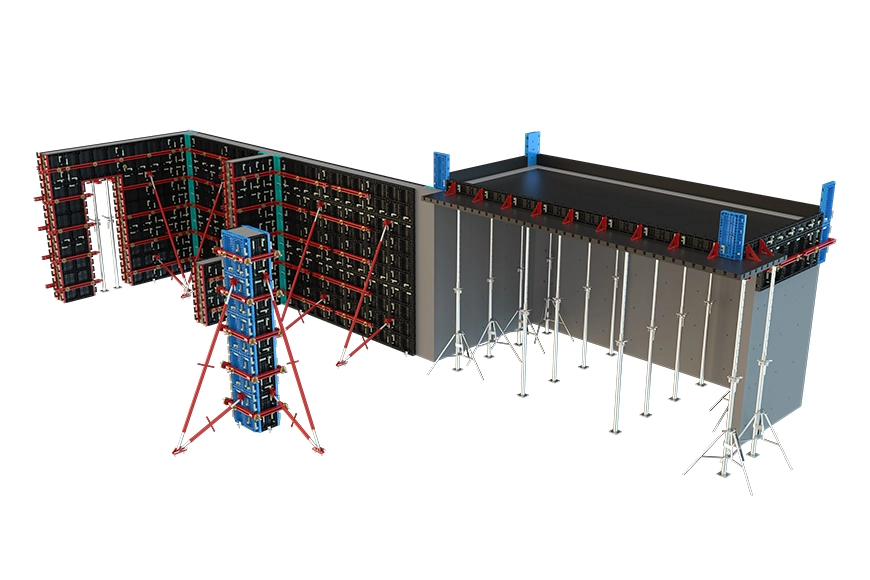

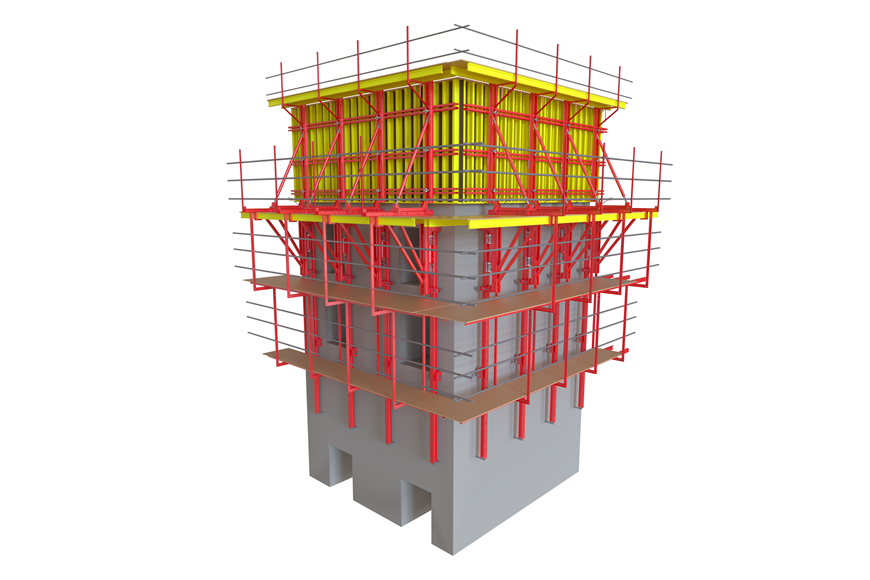

2. Before the installation of the column formwork, the edge of the axis column must be played well, and the elevation should be set on the steel bar. In addition to ensuring that the column formwork and support are firm and stable, the upper and lower formwork should also be supported on the same vertical centerline.

3. The back of the wall and system column formwork can be pasted with 50mm thick flame-retardant polystyrene board for insulation, and the relative gap of the insulation board can be increased by 1~2cm to ensure that the insulation board does not fall off. At the same time, it should be sealed with bamboo plywood or three plywood on the outside, and the bamboo plywood or three plywood should be disassembled and assembled at the same time as the building formwork.

4. The formwork for slab and beam should use 18mm thick multi-layer board; the beam bottom formwork should use 50mm thick pine planing; the floor formwork of the floor should use seven plywood or 18mm thick multi-layer board.

5. The formwork frame should be erected according to the requirements of the building formwork plan, and the support elevation and the arching height should be checked after the erection is completed.

1. When dismantling the formwork in winter, the formwork removal application should be submitted in accordance with the regulations, and the pressure test report of the formwork removal test block should be included, and the formwork removal operation can be carried out after the formwork removal application is approved.

2. The correct formwork removal sequence and method should be selected according to the provisions of building formwork design. If there are no specific provisions, it should be carried out according to the principle of first support and then removal, and the formwork of non-load-bearing parts should be removed first, and then the formwork of the load-bearing part should be removed.

3. In a positive temperature environment, the formwork can be removed if the edges and corners of the concrete and the surface layer will not be damaged due to the removal of the wall formwork; and in a negative temperature environment, the compressive strength of the demould test block should reach 4MPa and the concrete should be removed. The formwork can be removed when it is not frozen, and the removal time should also be strictly controlled.

4. When the temperature difference between the concrete and the outside environment is greater than 20°C, the concrete surface should be covered with polyethylene plastic sheet after the formwork is removed, and the surface should be temporarily covered with a straw bag to allow it to cool slowly.