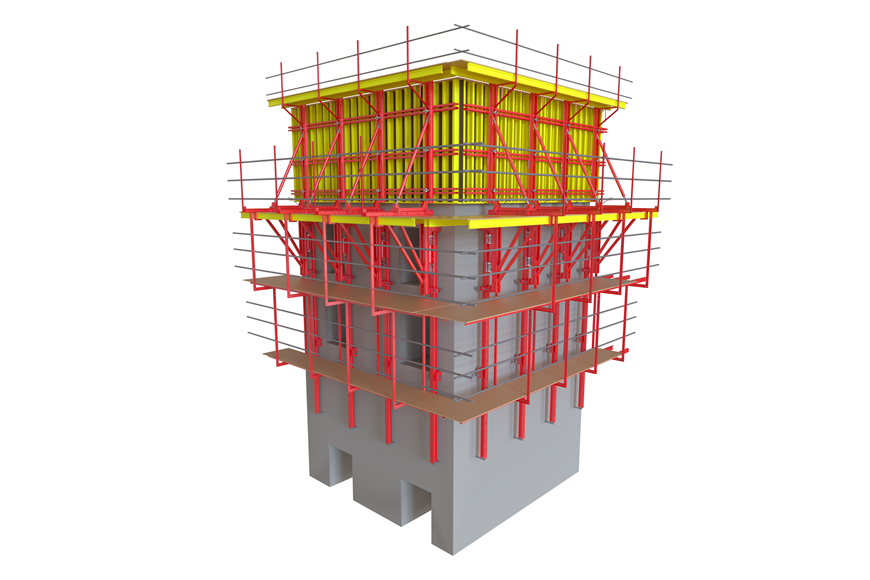

The building formwork directly uses the natural color of cast-in-place concrete as the finish. It is necessary to ensure that the surface of the formwork is flat and smooth during use, the color and gloss are uniform, and there is no bump and pollution. The setting of tension bolts and construction joints should be neat and beautiful, and common quality defects of ordinary concrete should not be allowed.

When designing formwork, the building formwork manufacturer must fully consider the convenience of assembly and dismantling, the firmness and simplicity of the support, and maintain good strength, rigidity, stability and flatness after the overall assembly.

The location, form and size of the joints of the building formwork, the tension bolts and the construction joints must be approved by the architect. According to the specifications and shapes of the components, different formwork materials are selected reasonably, and a quantity of stereotyped formwork is prepared for construction needs.

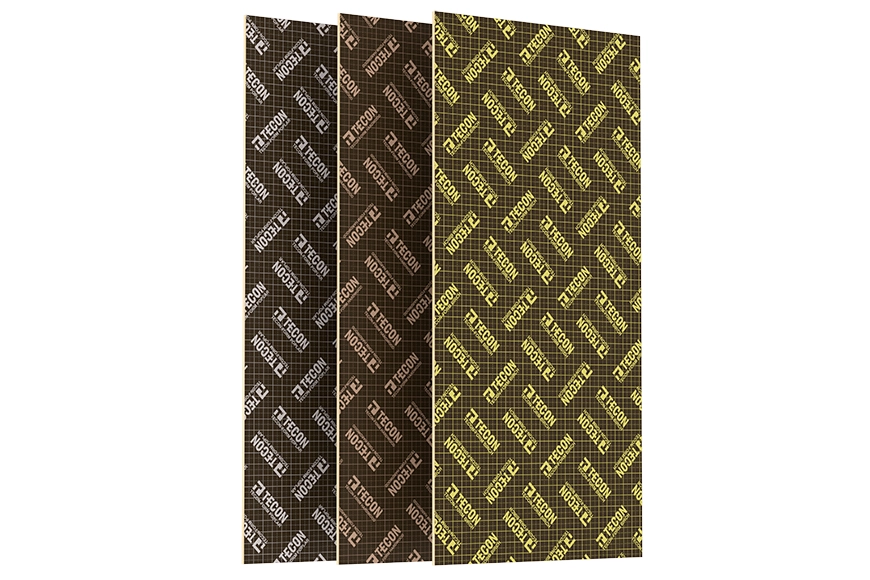

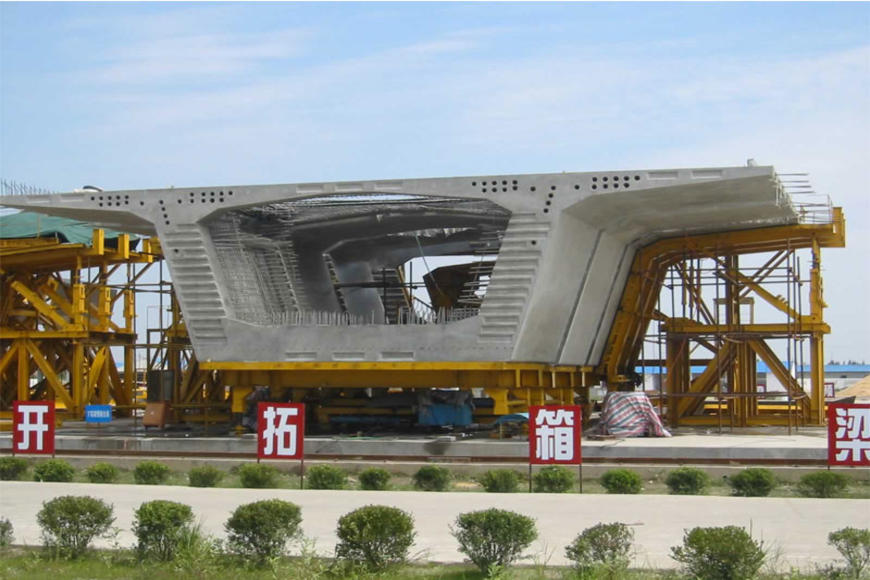

Steel formwork can be selected for circular components, and imported Finnish plates or plastic-coated plywood can be used for components with complex cross-sections such as E-shaped and T-shaped. The inner surface of the steel formwork should be polished to ensure the surface finish of the concrete. In addition, when making the formwork, it should be ensured that the geometric dimensions are accurate, the seams are tight, and the materials are consistent.

In order to achieve a perfect decorative effect for the use of building formwork, the joint treatment of the formwork must be tight. The formwork release agent should use colorless light engine oil with moderate water absorption, and the number of formwork turnover should be strictly controlled. Generally, after three turnovers, it should be overhauled and polished once.