The construction of the bridge formwork support and the choice of form have a great influence on the construction of the bridge, so the design of the bridge formwork support is becoming more and more important. Based on the safe use of the support, the article mainly studies the design and construction of the bridge formwork support from five stages: design, pre-compression, erection, acceptance, and demolition.

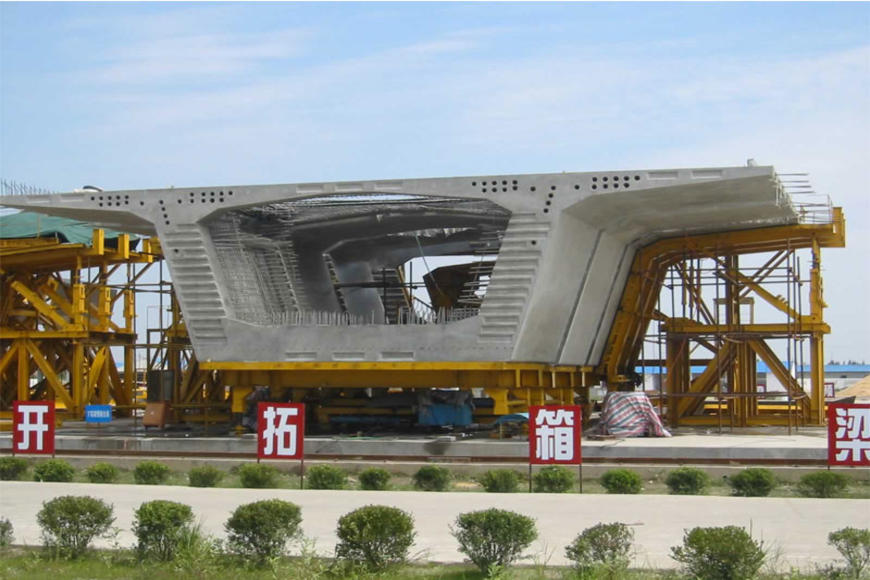

The main function of the bridge formwork support is to support the structure when the cover beam and main body of the bridge are poured, and to assist the formation of reinforced concrete materials. The load it bears is permanent load and variable load. Therefore, in the design of the bridge formwork support, multiple load combinations should be considered, and a reasonable formwork support system should be selected to ensure safe and reliable construction.

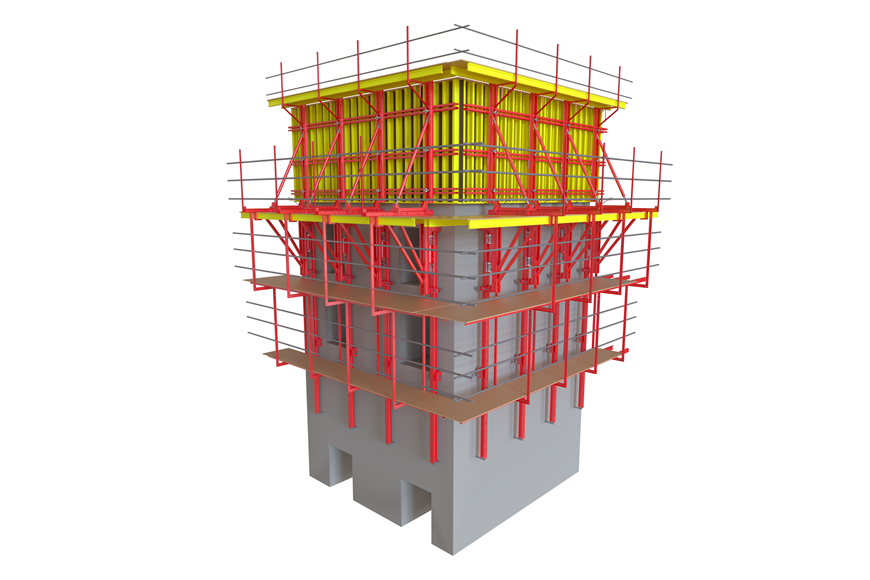

When designing the bridge formwork support according to the limit state of the structure in terms of bearing capacity, the reliability of the formwork support should meet the formula. When designing the bridge formwork support according to the structure's limit state in normal service, the reliability of the formwork support should meet the formula.

In the formula: The structural importance coefficient is 0.9 is the load effect combination is the maximum bearing capacity of the support.

Finally, according to the design specifications, the strength, rigidity, and stability of the bridge's beam bottom formwork, beam bottom girder, supports, etc., can be checked.

During the construction of the bridge, the support will produce elastic and inelastic deformation under the load, and the foundation will settle. Therefore, the support and the support foundation are often pre-compressed during the bridge construction to eliminate the uneven settlement of the foundation and the deformation of the support. The pre-compression load should be 1.05 to 1.1 times of the total load that the support bears during construction.

(1) Unified specifications and models.

(2) Strict control over materials.

(3) Personnel and machinery standards: relevant professionals need to pass the assessment and hold an on-the-job operation certificate. The relevant certificates of used machinery and equipment need to be verified.

(4) Recheck and calculation: After the result of rechecking is correct, the erection of the formwork can be started.

After the formwork support is erected, check and accept the support system according to the construction plan and related regulations. The inspection and acceptance of the bridge formwork support is a key step to ensure the safety of construction. Therefore, the acceptance stage should be carried out in strict accordance with the relevant regulations and specifications of the industry to ensure a comprehensive inspection and accurate acceptance.

Combining engineering practice, the following suggestions are put forward for inspection and acceptance:

(1) The bridge formwork support that will be used should be strictly inspected and accepted, and only after the acceptance is qualified it can be used.

(2) It is strictly forbidden to expand the distance between the supports to ensure the safety of the supports. If the step distance (1.2m) is expanded by 0.2m and the carrying capacity is reduced to 95%, it will not meet the requirements for use.

(3) Components with major problems in terms of material strength and stability shall not replace standard components, and such components shall be strictly controlled during construction.

(4) The construction unit and the supervision unit should conduct strict inspections of the supports, and the person in charge of the construction unit should conduct strict random inspections on the components to ensure that the quality of the components and materials meet the requirements.

The full support can be removed from the head to the foot one by one. The simply supported beam should be removed from the middle of the span to the support; when the formwork of multi-hole arch bridge is dismantled, if the pier is allowed to bear the load of construction with a single hole, it can be unloaded in the case of a single hole; Special personnel should be assigned to observe the deflection of the arch ring and the changes of the pier and abutment with instruments when the bridge formwork supports are removed, and make a record.